Bracing is the unsung hero of structural engineering. It’s what keeps buildings steady, absorbs seismic shocks, and balances the forces of nature—all while shaping the design and cost of a project. The right types of bracing isn’t just about stability; it’s about strategy, ensuring safety without breaking the budget.

In this article, we’ll break down the types of bracing, focusing on steel structures and how they combine strength, efficiency, and resilience to create designs that stand the test of time.

What is Bracing?

Bracing is the backbone of structural stability.

It’s the system that stands between your building and the forces of nature, designed to reinforce and stabilize against wind, seismic shifts, or the weight of heavy loads.

Bracing ties structural members together—diagonal, horizontal, or vertical—creating a unified framework that keeps buildings steady under stress.

Why Bracing Matters:

- Resisting Lateral Forces: Bracing acts as the first line of defense against wind and earthquakes, ensuring the structure remains upright and steady.

- Preventing Buckling and Collapse: It distributes stress evenly, safeguarding the building from critical failure under loads applied to it.

- Preserving Design Freedom: Bracing supports bold architectural visions, maintaining flexibility without sacrificing stability.

In steel structures, the types of bracing are especially critical. It doesn’t just strengthen—it transfers loads with precision, ensuring that every structure component works together to handle stress effectively.

Types of Bracing

At its essence, bracing is about balance and resilience, ensuring structures can stand strong against wind, seismic activity, and heavy loads. Bracing falls into three main categories, each playing a critical role in keeping buildings safe and stable:

1. Horizontal Bracing

Horizontal bracing acts like the connective tissue of a structure, tying beams and columns into a stable plane. It’s most commonly found in floors and roofs, where horizontal loads like wind or vibrations are distributed across the building.

Its key function?

Preventing horizontal movement, ensuring the entire framework absorbs and transfers forces effectively. By linking the structure’s components, it transforms the building into a rigid, interconnected system that stays strong under stress.

2. Vertical Bracing

Vertical bracing serves as the backbone of a structure, running from the foundation to the roof to resist both vertical and horizontal forces. Strategically placed at corners or along the height of structural frames, it’s essential in high-rise buildings or those in seismic zones.

It’s key function

Its primary job is to resist gravity and prevent lateral sway by evenly distributing vertical loads. Vertical bracing enhances structural strength and stability, guarding against failure, keeping the framework aligned and upright under pressure.

3. Diagonal Bracing

Diagonal bracing is the workhorse of structural reinforcement.

Is it a form of vertical bracing? Yes.

However, we felt it deserved a separate mention because its angled design is what truly enables the efficient transfer of lateral forces, ensuring stability.

Within diagonal bracing, there are four main types:

- Ordinary Concentrically Braced Frames (OCBFs)

- Special Concentrically Braced Frames (SCBFs)

- Eccentrically Braced Frames (EBFs)

- Buckling-Restrained Braced Frame (BRBF)

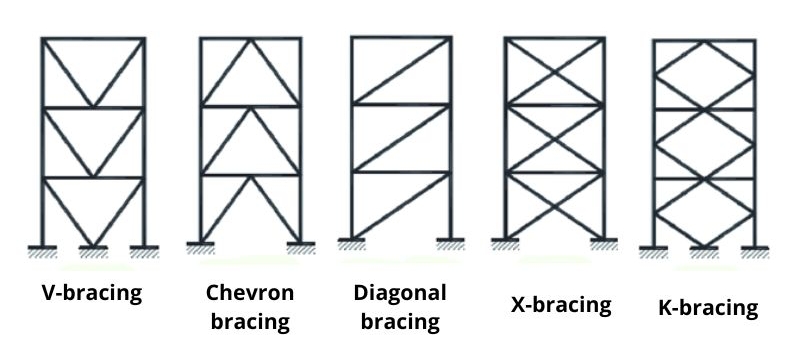

Diagonal bracing comes in several configurations, including cross bracing (X-shaped), K-bracing, V-bracing, and Chevron bracing. Each has its unique advantages, and we’ll dive deeper into their uses later.

Where It Works Best

Steel structures rely heavily on diagonal bracing. Each bracing type and configuration has its own strengths, fine-tuned to meet the unique demands of different structures. Together, they ensure every component works in harmony to maintain safety, stability, and resilience.

Now let’s see the different configurations.

Bracing Types in Steel Structures

Let’s clear up a common misconception.

When diving into the world of bracing, you’ll often see articles referring to the shapes of bracing as “types.” In reality, these shapes are known as bracing configurations.

The real “types” of bracing—like buckling-restrained braced frames—refer to the overall system that reinforces a structure.

Configurations are the geometric patterns that define how braces are arranged. These configurations aren’t just aesthetic—they play a critical role in distributing forces and shaping how a building performs under pressure. Getting them right isn’t optional; it’s foundational.

Cross Bracing (X-shaped)

Cross bracing uses two diagonal braces in an X-pattern to effectively distribute lateral forces. One brace resists tension while the other handles compression, making it a reliable choice for steel structures requiring maximum stability. However, its rigidity can block open spaces, complicate retrofitting, and clash with design aesthetics.

Diagonal Bracing

The simplest and most versatile option, diagonal bracing connects structural elements with a single angled brace. It efficiently transfers lateral forces, making it a common choice in both seismic and non-seismic zones. Diagonal bracing works seamlessly in a wide range of structures, but its simplicity can limit flexibility for certain designs.

Traditional seismic bracing methods, such as concentrically or eccentrically braced frames, are incompatible with diagonal bracing because these systems rely on one brace to handle tension while the other buckles under compression.

However, diagonal bracing pairs seamlessly with Buckling Restrained Braced Frames.

K-Bracing

With diagonal braces meeting at a single central point on a vertical column, K-bracing accommodates architectural elements like doors and windows by avoiding interference. That said, it’s not the best choice for seismic applications, as it leaves columns exposed to lateral forces without sufficient reinforcement.

Chevron and V-Bracing

Two diagonal braces form a V or ^-shape (inverted V) by connecting at a mid-beam point. This bracing allows for efficient load transfer while preserving flexibility for architectural needs, making it a practical choice in areas with limited space for bracing systems.

One-Way Bracing

This configuration connects one corner of the structure to the middle of a beam. While rare, it can be useful in specific cases where architectural requirements dictate this approach.

Eccentric Bracing

Eccentric bracing offsets the diagonal braces from the joint, creating a controlled deformation zone that absorbs energy during seismic events. This design minimizes damage to the main structure and reduces repair needs post-earthquake. While they’re effective, their complexity can make them a more expensive and time-consuming option compared to simpler bracing systems.

Each configuration offers unique benefits and trade-offs. Engineers carefully select bracing based on structural needs, seismic demands, and design goals.

Let’s see some examples.

Which bracing configuration should you use?

The shape of the bracing is also very unique to every project but usually these two factors determine it:

1. The Type of Bracing You Choose

The bracing system dictates what configurations are even possible.

For example, cross bracing is incompatible with buckling-restrained braced frames (BRBFs).

Why? Cross bracing relies on one brace working in tension while the other buckles under compression. However, BRBFs are specifically engineered to perform equally under both tension and compression, without buckling.

2. The Building’s Design

The layout and architectural design play a pivotal role in determining the bracing configuration. Factors like window and door placement or structural elements like stairways, elevators or open floors influence where and how braces can be installed.

For example, diagonal bracing can connect and stabilize multiple floors. In one of our projects in Turkey, the horizontal beam was open, allowing a diagonal brace to run continuously between two floors, effectively enhancing stability across the levels.

Picture a square, concrete elevator shaft—naturally robust and structurally strong. You might position bracing to support it floor by floor with a diagonal brace, or, like in the Turkey project, run it diagonally through multiple floors, seamlessly transferring loads.

There’s no universally “better” or “worse” bracing—it all depends on the structure’s specific needs and design constraints. But if we had to pick one, diagonal bracing would be our go-to. It’s highly efficient, seamlessly transferring horizontal and vertical loads diagonally down into the foundation, ensuring optimal stability and load distribution.

With Chevron, V, or K-bracing, the connection faces a unique challenge: one brace is in compression while the other is in tension. This push-and-pull dynamic puts extra stress on the beam holding the connection, making it more vulnerable during seismic or wind loads. As engineers, the solution is clear—you’d add another V bracing to the next level (if there is one) to ensure the loads transfer directly through, eliminating twisting in the connection.

It’s completely doable, but let’s be honest—it adds complexity. More connections, more design considerations, more care in execution.

And while we know architectural needs often call the shots (because, of course, they do), we’re structural engineers. For us, the ideal setup? A square room, one window, one door—the definition of simple, stable perfection.

But that’s the amazing thing about working together with architects:

Architects challenge us to step outside our structural comfort zone, to think beyond the perfectly balanced, stable box we love. Meanwhile, we challenge them to bring their creative visions back down to earth—literally—so they function in the real world. They focus on how the building should look and feel; we focus on how it will stand and endure. Together, it’s a collaboration that blends dreams with engineering precision.

Here you can find a research done on the influence of various types of bracing to the structural performance of buildings.

Seismic Bracing: Essential for Earthquake Resistance

Seismic bracing is designed to protect buildings during earthquakes by absorbing and redistributing the intense, multi-directional forces they generate.

Unlike conventional bracing, which targets wind or gravity loads, seismic bracing is purpose-built to handle the unique dynamics of seismic activity.

Its goal is clear: minimize structural damage, safeguard occupants, and maintain a building’s integrity during seismic events.

By controlling movement and deformation, seismic bracing reduces the risk of collapse and cuts down on repair costs. Systems like buckling-restrained braced frames, moment frames, and base isolation deliver the resilience and flexibility needed to keep structures stable when the ground shifts.

Let’s see them in a little more detail.

Common Seismic Resistance Systems

Buckling-Restrained Braced Frames (BRBFs):

As we already discussed BRBFs are engineered to handle both tension and compression forces without buckling, making them a standout choice for seismic zones.

These frames dissipate energy effectively, providing exceptional stability and minimizing structural damage during earthquakes. The key advantage is their high performance in reducing seismic forces while maintaining structural integrity. When you choose an all-steel brace like the Ever Brace, you also get a lower cost as an extra advantage.

Moment Frames

Moment frames rely on rigid connections between beams and columns to resist lateral forces. They allow controlled movement during seismic events while maintaining overall stability, making them ideal for buildings where open spaces are a priority, as they eliminate the need for diagonal bracing. The advantage is clear: design flexibility and unobstructed spaces. The downside is that they require meticulous construction and are generally less effective at dissipating energy compared to BRBFs.

Base Isolation

Base isolation separates the building from the ground using flexible bearings or sliders. This enables the structure to move independently of the earth’s motion. This system significantly reduces vibrations and protects the structure, making it particularly effective for critical infrastructure or high-value buildings. The advantage is unparalleled protection against seismic forces, but it comes with a hefty price tag and is better suited for specialized projects rather than standard construction.

In seismic design, selecting the right system involves weighing the advantages of performance, flexibility, and cost against the specific needs of the structure and site conditions.

We wrote about this in detail in this article: The Ultimate Guide to Buckling Restrained Brace Frames

Conclusion

Bracing isn’t just a structural necessity—it’s a thoughtful balance between engineering precision and architectural creativity. This article highlights two key insights:

- Configuration Shapes Performance: The configuration directly impacts how forces are absorbed and distributed. Getting this right is critical to both safety and design flexibility.

- System Matters as Much as Style: Choosing the right bracing system—like BRBFs for seismic resistance —can significantly influence a structure’s ability to endure and adapt.

By understanding the nuances of bracing, you’re not just ensuring structural stability—you’re empowering smarter, more resilient designs that endure both nature’s challenges and the test of time.

FAQs

What are the main types of bracing in steel structures?

The main types of bracing in steel structures include diagonal bracing (with configurations like cross, V, and Chevron), vertical bracing, and horizontal bracing. Each type plays a unique role in stabilizing the structure and resisting forces like wind, seismic activity, and heavy loads.

Which bracing type is best for seismic resistance?

Buckling-Restrained Braced Frames (BRBFs) are considered the gold standard for seismic resistance. They handle both tension and compression forces without buckling, making them ideal for minimizing structural damage during earthquakes. Other options can be Moment frames and Base isolation, which are better for more specialized projects.

How do vertical and horizontal bracing differ?

Vertical bracing strengthens the structure against both vertical and lateral forces, running from the foundation to the roof to resist sway and distribute loads. Horizontal bracing, on the other hand, stabilizes floors and roofs by tying beams and columns together, preventing horizontal movement and ensuring a unified, rigid framework.

What are the different types of frame bracing?

Frame bracing configurations include Cross Bracing (X-shaped) for maximum stability, K-Bracing to accommodate openings like doors and windows, V-Bracing and Chevron Bracing or Inverted V for efficient load transfer, and diagonal bracing for buckling restrained braces..

What is the most effective bracing system?

The most effective bracing system depends on the project: the design, the building’s environment, and the budget. For seismic bracing, BRB’s in diagonal configurations are one of the most stable options.